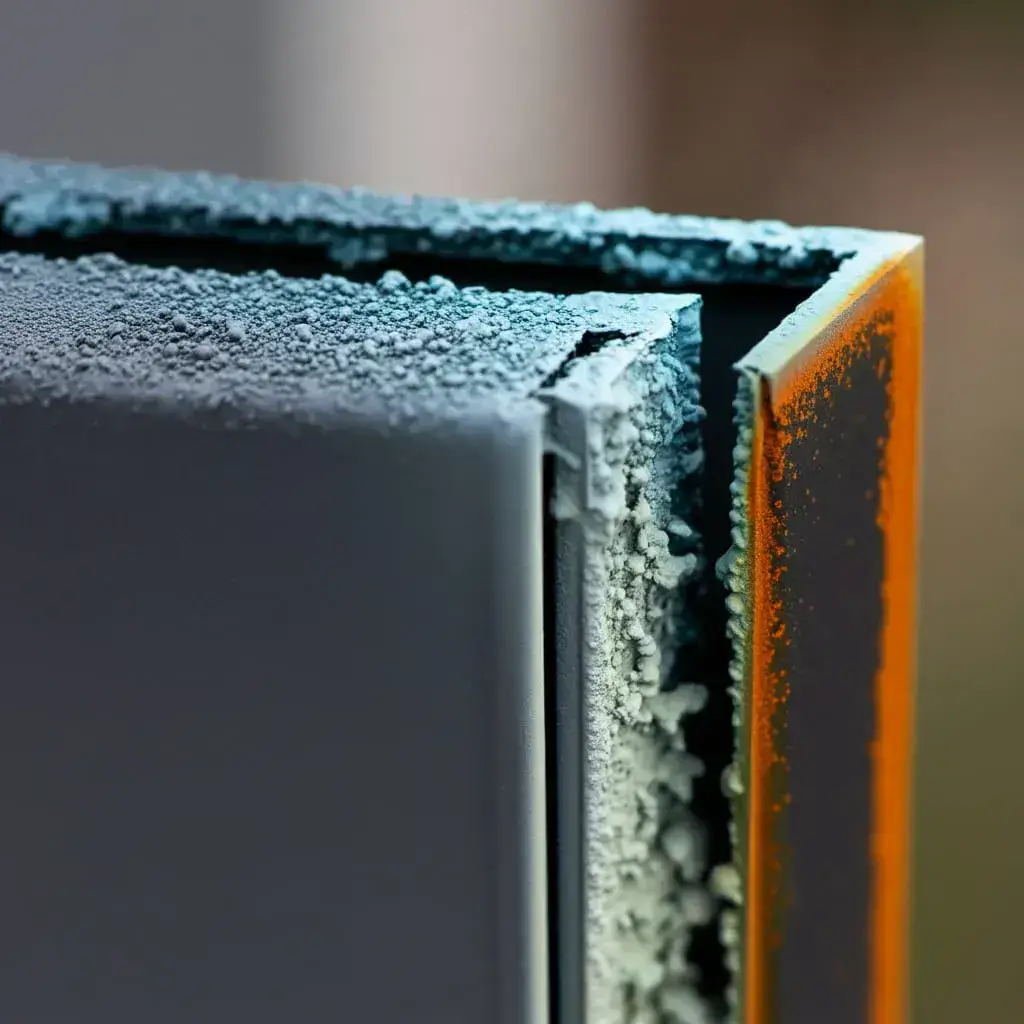

Cut-edge corrosion is a common issue that affects metal roofing and cladding, particularly around the edges of metal sheets, laps, and ends. If left untreated, this corrosion can lead to structural damage, leaks, and costly repairs. At Inspire Spray Coat, we offer professional cut-edge corrosion treatment services to protect your property and prevent further deterioration.

Our tailored approach ensures long-lasting results, helping you maintain the integrity of your building while avoiding the expense of complete roof replacement.

Cut-edge corrosion occurs when the protective coating on metal cladding sheets fails at the edges, leading to the metal being exposed to the elements. This exposure results in rust and corrosion, which can spread and compromise the structural integrity of your roofing or cladding. Recognizing the early signs of cut-edge corrosion is crucial in preventing extensive damage and costly repairs.

Our expert team is trained in identifying and treating cut-edge corrosion using advanced coatings and products from trusted brands. We work closely with you to develop a customized solution that meets your building’s specific needs and budget.

During an on-site consultation, we’ll assess the severity of the corrosion and recommend the appropriate treatment for your property, ensuring a comprehensive approach that prevents future issues.

Our cut-edge corrosion paint coatings are highly durable, offering long-term protection against corrosion and wear. Once applied, these coatings extend the lifespan of your metal surfaces, minimizing the need for ongoing repairs.

Available in a variety of colours, cut-edge corrosion coatings can enhance the appearance of your building, ensuring that your property looks as good as it is protected. This can also help align the look of your building with your brand’s aesthetic.

Compared to full roof or cladding replacement, cut-edge corrosion treatments are a cost-effective solution. By addressing the problem early, you can save on the more significant costs associated with repairing or replacing damaged sections of metal roofing.

The coatings are easy to apply using airless spray technology, ensuring an even and smooth finish. This application method allows for quick treatment with minimal disruption to your business.

The primary function of our corrosion-resistant coatings is to protect metal surfaces from further corrosion. By sealing vulnerable areas, you can preserve the strength and integrity of your roof or cladding.

Our team has extensive experience treating metal surfaces affected by cut-edge corrosion, ensuring reliable and long-lasting results.

We tailor our approach to your specific property, offering solutions that meet both your needs and budget.

Our treatments are applied quickly with minimal disruption to your business operations, allowing you to maintain normal working conditions.

We use advanced coatings and products from reputable brands to guarantee the highest quality of service.

For a free no-obligation quote or to discuss your requirements, please contact us today.

Mon – Fri

8:00 AM – 6:00 PM

Saturday

9:00 AM – 5:00 PM

Sunday

Closed

Our treatments typically last 10 years or more, depending on the type of metal and environmental exposure. Regular inspections and maintenance can further extend the life of the treatment.

Yes, our treatments are suitable for a wide range of metal surfaces, including steel and aluminium roofing and cladding. We will assess your property to recommend the best solution.

Absolutely. Cut-edge corrosion treatments are a fraction of the cost of replacing damaged metal, making them a cost-effective solution for extending the life of your roof or cladding.

The application process is fast, typically taking 1-2 days, depending on the size of the project. We work efficiently to minimize downtime for your business.

Get in touch with us for a free quotation in less than 24 hours. Enjoy 10% off when you book this week! *Upon acceptance of our services or any discounts, a non refundable deposit is payable

Verify to start chat: